We are committed to you

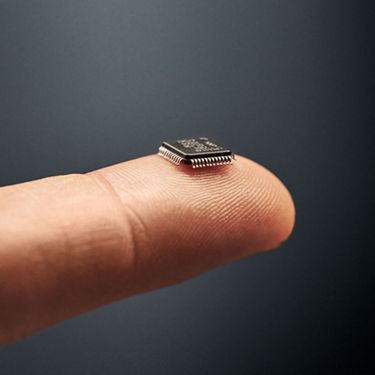

The automotive industry is currently affected by the limited availability of semiconductors resulting in global supply chain delays. Therefore, we at Audi are working tirelessly to deliver your dream car as quickly as possible. We invite you to get to know some of Audi's employees, their responsibilities, and the passion they bring to the challenges they face. Because you can rest assured: We stand by our commitment to perfection and focus on service excellence.